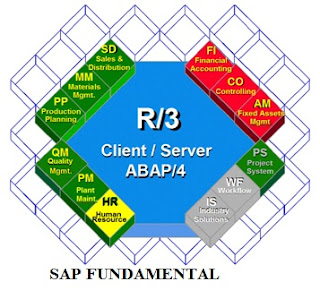

SAP FUNDAMENTAL

Currently in SAP has twelve modules; some of them are integrated by the combination of other modules:

Financial Accounting (FI): An important core module, designed for meeting all the accounting and financial needs of an organization. Within this module Financial Managers as well as other Managers within your business can review the financial position of the company in real time.

Controlling (CO): Represents the company’s flow of cost and revenue, offers all the support information needed by Management for the purpose of planning, reporting and decision making. Decision making can be achieved with a high level of information reducing drastically risks. Basically It is a management instrument for organizational decisions.

Sales & Distribution (SD): The SAP sales and distribution is part of the logistics module that support your customers, starting from quotations, sales order and all the way towards billing the customer. It is tightly integrated with the MM (Material Management) and PP (Product Planning) functional modules. It allows companies to input their customer sales price, check for open orders and forecast etc.

Material Management: (MM): Is the materials management module of the SAP. This module is used for Procurement Handling and Inventory Management. Materials management (MM) is integrated with other modules such as SD (Sales & Distribution), PP (Product Planning) and QM (Quality Management). Materials management is used for procurement and inventory management.

Product Planning (PP): The purpose of PP&C (Production Planning and Controlling) is to ensure that manufacturing runs effectively and efficiently and produces products as required by customers. The Production Planning module of SAP takes care of Master data needed like Bill Of Materials, Routings and Work Centers and stores it in one separate component.

Quality Management (QM): Quality management is a method for ensuring that all the activities necessary to design, develop and implement a product or service are effective and efficient with respect to the system and its performance. Quality management is the comprehensive solution that supports the company throughout the product life cycle and along the supply chain.

oriented to cover all maintenance activities, supporting the Planning, Programming and Implementation, with emphasis on the availability of equipment, staff costs and Assurance, guaranteeing so the state of the art of database and optimization. SAP’s Plant Maintenance comprises of the following activities such as inspection, to measures and establishes the actual condition of a technical system, preventive maintenance to measures and maintain the ideal condition of a technical system, repair to measures and restore the ideal condition of a technical system and other measures that need to be taken using the maintenance organization.

Human Resources (HR): It deals with various activities done in the human resource department of an organization, such as, Personal administration, personnel development, training and event management, payroll etc. This module enables customers to effectively manage information about the people in their organization, and to integrate that information with ”other SAP modules” and external systems.

Project System (PS): Created to support the planning, control and monitoring of long-term, highly complex projects with defined goals .Projects are generally part of the internal processes of a company. To be able to control all tasks in project execution, you need an organizational form that is specific to the project and which is shared by all departments involved.

Plant maintenance

IW21

|

Create Notification

|

IW28

|

Notification List Editing - Change

|

IW29

|

Notification List Editing - Display

|

IW30

|

Notification List Editing - Display Multi Level

|

IW31

|

Create Plant Maintenance Order

|

IW32

|

Change Plant Maintenance Order

|

IW33

|

Display Plant Maintenance Order

|

IW34

|

Create Notification Order

|

IW38

|

Work Order List Editing - Change

|

IW39

|

Work Order List Editing - Display

|

IW40

|

Work Order List Editing - Display Multi Level

|

IW41

|

Time Confirmation - Individual Entry

|

IW42

|

Overall Completion Confirmation

|

IW44

|

Time Confirmation - Collective Entry no Selection

|

IW48

|

Time Confirmation - Collective Entry with Selection

|

IW51

|

Create Service Notification

|

IW52

|

Change Service Notification

|

IW53

|

Display Service Notification

|

IW54

|

Create Service Notification :Problem notification

|

IW55

|

Create Service Notification :Activity Request

|

IW56

|

Create Service Notification :Service Request

|

IW57

|

Assign deletion Flag to Completed Service Notifications

|

IW58

|

Change Service Notifications: Selection of Notification

|

IW59

|

Display Service Notifications: Selection of Notification

|

IW64

|

Change Notification List of Activities

|

IW65

|

Display Notification List of Activities

|

IW66

|

Change Notification List of Tasks

|

IW67

|

Display Notification List of Tasks

|

IW68

|

Change Notification List of Items

|

IW69

|

Display Notification List of Items

|

IA07

|

Display General Task List

|

IA03

|

Display Equipment Task List

|

IA13

|

Display Functional Location Task List

|

IR03

|

Display Work Centre

|

KO88

|

Settle Order (Single)

|

ME21

|

Create Purchase Order (pre R4.6)

|

ME21N

|

Create Purchase Order (R4.6 onwards)

|

IP41

|

Create Single Cycle Plan (R4 onwards)

|

IE02

|

Change Equipment

|

IE01

|

Create Equipment

|

IE03

|

Display Equipment

|

IE05

|

Equipment List Editing - Change

|

IE08

|

Equipment List Editing - Display

|

QS42

|

Display Catalog

|

ML81

|

Create Service Entry Sheet

|

MM03

|

Display Material

|

CS03

|

Display Material BOM

|

IH01

|

Display Functional Location Structure

|

MB11

|

Goods Movement

|

MB31

|

Goods Receipt

|

IW8W

|

Goods Receipt for Refurbishment (R4 onwards)

|

IP02

|

Change Maintenance Plan

|

IP03

|

Display Maintenance Plan

|

IP10

|

Schedule Maintenance Plan

|

IP30

|

Deadline Monitoring

|

IP11

|

Change Maintenance Strategy

|

IP12

|

Display Maintenance Strategy

|

IP19

|

Maintenance Scheduling Overview Graphic

|

IP24

|

Maintenance Scheduling Overview List

|

IQ03

|

Display Serial Numbers

|

IP42

|

Create Strategy Maintenance Plan (from R4 onwards)

|

IL02

|

Change Functional Location

|

IL01

|

Create Functional Location

|

IL03

|

Display Functional Location

|

IL05

|

Functional Location List Editing - Change

|

IL06

|

Functional Location List Editing - Display

|

IA11

|

Create Functional LocationTask Lists

|

IA12

|

Change Functional Location Task List

|

IL02

|

Change Functional Location

|

IA05

|

Create General Task List

|

IA06

|

Change General Task List

|

IA01

|

Create Equpment Task List

|

IA02

|

Change Equipment Task List

|

IE03

|

Display Equipment

|

IR01

|

Create Work Centre

|

IR02

|

Change Work Centre

|

CA85

|

Replace Work Centre

|

IP13

|

Strategy Package Sequence

|

IP14

|

Strategy Package Sequence

|

IP04

|

Create Maintenance Item

|

IP05

|

Change Maintenance Item

|

IP06

|

Display Maintenance Item

|

IP17

|

Maintenance Item List Editing - Change

|

IP18

|

Maintenance Item List Editing - Display

|

IP02

|

Change Maintenance Plan

|

IP03

|

Display Maintenance Plan

|

IP15

|

Maintenance Plan List Editing - Change

|

IP16

|

Maintenance Plan List Editing - Display

|

IK11

|

Create Measurement Documents

|

IK12

|

Change Measurement Documents

|

IK13

|

Display Measurement Documents

|

IK22

|

Measurement Documents List Editing - Create

|

IK21

|

Measurement Documents List Editing - Create

|

IK22

|

Measurement Documents List Editing - Create

|

IK18

|

Measurement Documents List Editing - Change

|

IK17

|

Measurement Documents List Editing - Display

|

IK41

|

Measurement Documents List Editing - Display Archive

|

IQ01

|

Create Serial Numbers

|

IQ02

|

Change Serial numbers

|

IQ04

|

Serial Numbers List Editing - Create

|

IQ08

|

Serial Numbers List Editing - Change

|

IQ09

|

Serial Numbers List Editing - Display

|

IK01

|

Create Measurement Point

|

IK02

|

Change Measurement Point

|

Ik03

|

Display Measurement Point

|

IK08

|

Measurement Point List Editing - Change

|

Ik07

|

Measurement Point List Editing - Display

|

SAP Transaction Codes in Material Management

ME01

|

Maintain Source List

|

ME03

|

Display Source List

|

ME04

|

Changes to Source List

|

ME05

|

Generate Source List

|

ME06

|

Analyze Source List

|

ME07

|

Reorganize Source List

|

ME08

|

Send Source List

|

ME0M

|

Source List for Material

|

ME21

|

Create Purchase Order

|

ME21N

|

Create Purchase Order

|

ME22

|

Change Purchase Order

|

ME22N

|

Change Purchase Order

|

ME23

|

Display Purchase Order

|

ME23N

|

Display Purchase Order

|

ME24

|

Maintain Purchase Order Supplement

|

ME25

|

Create PO with Source Determination

|

ME26

|

Display PO Supplement (IR)

|

ME27

|

Crea e Stock Transport Order

|

ME28

|

Release Purchase Order

|

ME29N

|

Release purchase order

|

SAP STEP BY STEP

PM & MM MODULE

1. PURPOSE:

Order creation for material issue

Order closing when job over

MIV posting

Order review

Notification to generate

Notification closing

Fund centre, fund, and cost centre GL a/c

SES via order

PR creation –material

-service

Release

Change

Vendor code creation

2.TRANSACTION CODE

IW22 - Plant Maintenance -> Maintenance Processing -> Notification -> Change

IW28 - Maintenance Processing -> Notification -> List Editing -> Change

IW38 - Maintenance Processing -> Order -> Order List -> Change

YM15 - Inventory Management -> Reservation -> Print Reservation

MMBE - Inventory Management -> Environment -> Stock -> Stock Overview

IW33 - Plant Maintenance -> Maintenance Processing -> Order -> Display

IW33 - Service Processing -> Order -> Service Order -> Display

ML83 - Materials Management -> Service Entry Sheet -> Print/Transmit

IW32 - Plant Maintenance -> Maintenance Processing -> Order -> Change

ME22N - Materials Management -> Purchasing -> Purchase Order -> Change

ME23N - Materials Management -> Purchasing -> Purchase Order -> Display

ME51N - Materials Management -> Purchasing -> Purchase Requisition -> Create

ME2L - Purchasing -> Purchase Order -> List Displays -> By Vendor

ML81N - Logistics -> Materials Management -> Service Entry Sheet -> Maintain

ME53N - Materials Management -> Purchasing -> Purchase Requisition -> Display

YM11 - Purchasing -> Purchase Requisition -> Print -> Material

YM17 - Purchasing -> Purchase Requisition -> Print -> Services

ME2N - Purchasing -> Purchasing Documents -> Purchase Orders -> By PO Number

YMV - Vendor Creation / Extension Module

3- Maintenance Processing -> Notification -> List Editing -> Change

IW28

Notification date

Main work centre: OFFSIT-E

NPBLDG-E

SRU-E

PLANNING PLANT: …PLANT CODE…….

PLANNING GROUP: CPE

←Ι

4. ORDER CREATION FROM NOTIFICATION

IW28 -

Notification date

Main work centre: OFFSIT-E

NPBLDG-E

SRU-E

PLANNING PLANT: ……PLANT CODE----

PLANNING GROUP: CPE

SELECT NOTIFICATION

GO TO

NOTIFICATION

ORDER (GENERATE ORDER)

GO TO ASIGNMENT

FUND MANAGEMENT

FUND CENTRE

FUND

←Ι

5. NOTIFICATION CLOSIBG

IW28 -

Notification date

Main work centre: OFFSIT-E

NPBLDG-E

SRU-E

PLANNING PLANT: …..PLANT CODE….

PLANNING GROUP: CPE

SELECT NOTIFICATION

GO TO

NOTIFICATION

PUT IN PROCESS (GREEN FLAG)

GO TO ASIGNMENT

FUND MANAGEMENT

FUND CENTRE

FUND

←Ι

COMPLETE TECHNICALLY (BLACK FLAG)

6. ORDER CREATION

IW31

ORDER TYPE---PMP2

PRIORITY---IMMEDIATE

FUNCTIONAL LOCATION: 9060-099-TO-NS-IP

←Ι

ORDER PMP2------STREET LIGHT MAINTENANCE

GO TO

ASSIGNMENT

FUND MANAGEMENT

FUND

←Ι

GREEN FLAG

SAVE

6. ORDER OPEN REVIEW

IW38

MAIN WORK CENTRE ---NPBLDG-E

PLANT WORK CENTRE –9060

PERIOD----- TO ---------

PLANNING PLANT----9060

←Ι

7. ORDER CLOSING

IW38

MAIN WORK CENTRE ---NPBLDG-E

PLANT WORK CENTRE –9060

PERIOD----- TO ---------

PLANNING PLANT----9060

←Ι

COMPLETE TECHNICALLY

8. ORDER CLOSING WHEN ORDER IS KNOWN

IW32

SELECT

GO TO

ASSSIGNEMNET

FUNDMANAGEMENT

FUND 2120

RELEASE

COMPLETE TECHNICALLY

DATE

TIME

ENTRE

9. EXCELL SHEET

INFORMATION SYSTEM

LOGISTIC

PURCHASE DOCUMENT

PO NO

BY PO NO

ENTER

ITEM SELECT

GO TO

SERVICE

LOCAL FILE

SPREED SHEET

ENTER

FILE NAME

GENERATE

DESK TOP

REARRANGE

9. PR CREATION

MATERIAL

SERVICE

ME53N

CREATE

ACOOUNT ASIGNMENT

ITEM CATEGORY --- SERVICE ----MATERIAL

DEPARTMENT –EE

TRACKING NO.-----

CRCY ---INR

DELIVERY DATE CATEGORY

DELIVERY DATE

MATERIAL GROUP-

PLANT -9060

PURCHASE GROUP –R52

10.PR RELEASE

ME54

PR NO ---

RELEASE CODE ----

SELECT

RELEASE

SAVE

11.PR RESET

ME54

PR NO ----

EDIT

RELEASE

RESET

SAVE

12. MATERIAL CODE EXTENSION +MATERIAL SPECK CHECK

YMC

MATERIAL CODE ----

PLANT -9060

STORAGE LOCATION ---REVENUE

13. SOLUTION MANAGER

YSM

ID---9060

PASSWORD –9060

14. VENDOR CODE CREATION FORMAT

DOCUMENT -

LETTER PAD

PAN COPY

TRANSACTION CODE-YMV

VENDOR CREATE

STATUS

MY REQUEST ----

15. E-PAYMENT LOADING

PAN CARD

BANK DETAIL

BLANK CHEQUE

REQUISITION ON LETTER HEAD

BANC A/C

OWN REFERENCE NO

A/C TYPE ---29 CC

-----11 CA

ATTACHMENT ---FILE IN SOFT COPY ---PDF FORMAT

16. CREATE NOTIFICATION

IW21

TYPE –P2

ENTER

NOTIFICATION ----BEARING ABNORMAL SOUND

FUNCTIONAL LOCATION

PLANNER GROUP

MAIN WORK CENTRE

REPORTED BY----NAME

PRIORITY

17.ORDER PRINT

T-CODE ME23N-

Purchase order……………………..

√ Print preview

Dummy

→ (enter) NEV

NEW

PDF

PDFS

18. MATERIAL FROM AF

CN22

NETWORK-500002999

GREEN BUTTON

ACTIVITY REVIEW

INDENT OF MATERIAL

PLACEMENTOF PO

DELIVERY MATERIAL

INSTALLATION AND COMMISSIONING

ACTIVITY→COMPONENT OVERVIEW

MATERIAL CODE

PFR

19. FIND VENDOR CODE NO

XK03

VENDOR-------------√ (drop down)

Vendor by co code

Search term-----

Postal code-----

City-----

Name----

Vendor----

Company code---9060—

20. MATERIAL CONSUMPTION STATEMENT

YM54

WORK ORDER NO -----

PLANT----

℗

21. MATERIAL SEARCH BY GROUP( all material in that group)

MM60

MATERIAL-----

PLANT----9060--

MATERIAL TYPE----

MATERIAL GROUP------78—

22. PR SEARCH FOR TRACKING NO.

ME5A

PURCHASE REQUISITION ----------(DROP DOWN)√

TRACKING NO------906TE00086--

PURCHASE GROUP-----R08--

ENTER

23.PR SEARCH FOR material code .

ME5A

Purchase group---R08

Material group----78

Plant -9060--

Enter

24. Display Functional Location

T-code: IL03

Functional location ------Ө√

Click drop down

T-Code: YM108

Department are given as under :

CI Centralised / Inventory item

CL Maint-Civil

EC Engg/Consul-Contract

EE Maint-Electrical

EO Maint-Town/Estate

ES Eng. Services (All)

FI Finance

FS Fire & Safety

HR HR / P&A

IC Inventory Control

IN Instrumentation

IS Information systems

MA Maint-All discipline

MI Maint & Inspection

ML Maint-Mainline

MM Materials Management

MN Maint-Mechanical

MR Marine

OH Medical, OH & S

OP Operations

OT Others

PJ Projects

PN Oper. & Production

PU Operations - P&U

QC Quality Control

SE Safety/Health & Envir

SP Shipping

TC Telecommunications

TR Training/HRD

TS Tech. Services/ Co-ord

COST CENTRE or fund centre

Choose any order no….

- T-code –IW32

- ORDER NO…….(FILL)

- HEADER DATA

- GO TO

- ASSIGNMENT

- FUND MANAGEMENT

- FUND CENTRE ----- √drop down box

- Fund centre ---R06*

- Fm AREA –IOCL

- √ENTRE

ACCOUNT ASIGNMENT

| A | Asset | Release | Description |

| B | MTS prod./sales ord. | ||

| C | Sales order | 1 | Request for quotation |

| D | Indiv.cust./project | 2 | RFQ/purchase order |

| E | Ind. cust. w. KD-CO | 3 | RFQ/PO no change of date |

| F | Order | 4 | RFQ/PO no changes |

| G | MTS prod./project | A | PR approved |

| H | OMC - Cost center | B | Fixed RFQ/purchase order |

| K | Cost center | C | Pending Initiator Approval |

| M | Ind. cust. w/o KD-CO | D | Pending HOD Approval |

| N | Network | E | Pending DGM or above Approval |

| P | Project | F | Pending Finance Concurrence |

| Q | Proj. make-to-order | G | Pending GM or above Approval |

| S | Non-Valuated Receipt | H | Pndng DGM/CM or above approval |

| T | All new aux.acc.ass. | S | Pending Mgr or abov approval |

| U | Unknown | U | Pending Unit Head Approval |

| W | WBS CONSUMPTION | ||

| X | All aux.acct.assgts. | ||

| Y | W/o Cost center | ||

| Z | Maintenance-Services |

more study log on : http://www.saptrainingguy.blogspot.in/

Hi sir,

ReplyDeleteNice to know ur blog. I am a MV swtichgear testing engineer in schneider electric indonesia. I got a bachelor degree at power system Electrical Engineering. This is my first job, I graduated at 2015. I am keen to learn SAP, because I think it will give me a glance regarding business process. I want to ask you, is SAP worth studying? Because Iam not planning to be a SAP consultant. Thx for your response.

Regards,

Denny

Thanks for Sharing a Very Informative Post & I read Your Article & I must say that is very helpful post for us.

ReplyDeletePlant Engineering services in Minnesota

3d Laser Scanning Services in California

Electrician Mississauga

ReplyDeleteelectrical repair services

ReplyDeleteair conditioner installation