Tuesday, 22 November 2022

Separation distance between Electrical Substation and petroleum facility

Sr. References: - Conclusion Remarks

1 Petroleum and Natural Gas Regulatory Board- 2016, Annex-1, point 7: Elect Substation or Switch Yard or Transformers shall be installed average 30 meter far from petroleum Equipment.

2 Minutes of the 3rd Meeting of the Standing Committee on Electrical Safety held on 3rd August, 2018 at Surajkund, Haryana. 1. The angle of crossing of oil/gas pipeline by electric transmission line should be 90 degrees as far as possible. However, if there is any problem in the crossing, the angle of crossing in any case should not be less than 60 degrees.

2. The crossing of the pipeline of petroleum/natural gas by any transmission line shall be done from at least not less than 8 meters height.

3. No Tower footing/ structure of the overhead line of 33 kV AC and above/ HVDC shall be closer than 25 meters to the edge of the Right of way of a petroleum/natural gas pipeline.

3 OISD 118, Sr.Number:OISD/DOC/2016/1, annex-1, Tab-1 Separation distances between blocks/facilities-

a) Between Electrical Sub Station –class –A(Class-A Petroleum: Liquids which have flash point below 23oC.) -------------------------------------60M

b) Between Electrical Sub Station –class –B (Class-B Petroleum: Liquids which have flash point of 23oC and above but below 65oC.) --------30M

c) c)Between Electrical Sub Station –class –C(Class-C Petroleum: Liquids which have flash point of 65oC and above but below 93oC.) --------15M

4 EIL The electrical equipment for hazardous areas shall be selected as per IS-5571 and petroleum rules

Bhagwan Prasad

Electrical chartered Engineer

Regist No.M-1719887

Wednesday, 28 September 2022

Condition monitoring

Condition monitoring

Condition monitoring programs allow teams to move from reactive to predictive maintenance. Aggregating around-the-clock measurements provides teams with a clear picture of asset health and performance without expending labor. A condition monitoring program can also:

• Decrease maintenance costs

• Improve downtime response

• Move teams to condition-based maintenance

Save costs on prematurely changed resources

How to get the most value from condition monitoring

Condition monitoring strengthens your maintenance and reliability program by:

Gain continuous, always-on monitoring of assets

When internet-enabled devices are connected to software, real-time measurements are automatically aggregated around the clock. Data is stored in the cloud where it is assigned to assets and organized for users to review.

Identify the root cause faster

Teams can swiftly troubleshoot assets using different condition monitoring devices, such as vibration sensors or power monitors. Compare measurements over time to quickly pinpoint abnormalities.

Monitor equipment safely from anywhere

Connect your people and assets with remote sensors and mobile access. Measurements from wireless sensors are automatically sent to the cloud without human intervention or error. Teams can access data remotely from smart devices anywhere there’s an internet connection.

Courtesy: fluke

Sunday, 18 September 2022

Space planning for Event , meeting, conference, class room, dance floor, auditorium etc in India

Event planners plan many meetings, galas, and conferences. They have to plan for sitting capacity. Attendees don’t enjoy events that are overcrowded and difficult to navigate, so calculating event capacity is a critical step in planning. Thumb rule –

Sr. Event type Space required

(per person /Sqft) Remarks

1 Standing crowd 6’ Ex- A hall of 20’x30’ can accommodate 100 persons

2 Mixed seated and standing crowd 8’

3 Reception style seating with a dance floor 9’

4 Classroom-style seating 15-16’

5 Auditorium-style seating 6-8’

6 Conference table 30’

7 Theater or auditorium style seating 6-8’

8 Dinner seating at rectangular tables 9-10’

9 Dinner seating at round tables 11-12'

10 Dance floor 5’

11 DJ booth 200’

12 CEO table for 8 guest 100’

13 Bar 100’

Other: Space required for a corporate presentation.

It is required to provide slide and video presentation. The entire room won’t be packed wall-to-wall with chairs. It is advisable to visit the site and collect actual dimension and then plan. Typically seat back to seat back, 40 inches of space required. This provides attendees little space to move/pass each other.

Distance between screen and farthest viewer = screen size/4. The above is just for guideline. Please consult any architecture or verify physically.

Sunday, 20 March 2022

Tips on hot work in hazardous area

Explore alternate method:

Whenever possible, hot work should be avoided in hazardous industry or in chemical factory

Analysis of hazard of hot work:

Analysis of hazard should be carried out before staring of hot job like welding, grinding, drilling etc. Identify potential of hazards, consequence and its control.

Conduct surrounding test:

Conduct gas test in the work area and its surround using a Calibrated gas detector prior to and during hot work activities, even in areas where a Flammable atmosphere is not anticipated. During entire welding job, monitor continuously in the vicinity of storage tanks and other containers.

Stop another operation activity of chemical transfer or handling

There is chance of leakage or flow of chemical during nearby operation and may lead flammable gas or liquid.

Valid Permits

Ensure that qualified personnel familiar with the specific site hazards is doing hot work and issue permits specifically identifying the work to be conducted and the required precautions.

Provide training

Short training should be arranged periodically covering the topic

hot work policies/procedures, proper use and calibration of combustible gas detectors, safety equipment, and job specific hazards in a language understood by the welder/technician.

Supervisor

Supervisor should be motivated and deployed for contract workers. Supervisor should be sensitized about site-specific hazards including the presence of flammable materials

Carry out tool box talk weekly or when new job starts. Convey to analyze and understand the situation and to prepare them to take preventive action before it could occur.

Saturday, 5 March 2022

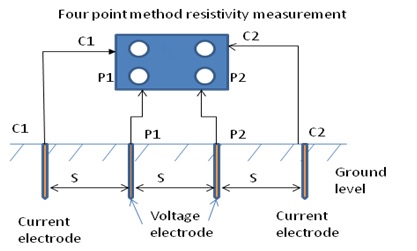

Measurement of Earth resistivity

Earth tester is used for the measurement of resistivity. As shown, instrument reads the resistance directly. The most frequently used earth tester is the four point method .The resistivity is calculated from equation as given below:

P=2πSR, where

• P = Resistivity of soil in ohm-meter

• S = Distance between successive electrodes in meter.

• R = earth tester reading in ohms.

The Four electrodes are driven into the earth along a straight line in a chosen direction at equal spacing (formula may not be successful on unequal spacing). The depth of electrodes in the ground is taken generally 6”.The earth tester is placed on even surface. The link between terminals P1 and C1 is opened and the four electrodes are connected to the instrument terminals. An approximate range on the instruments is then selected to obtain clear readings, avoiding the two ends of the scale as far as possible. Reading are taken and averaging is done using the formula.

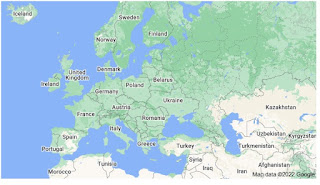

to integrate renewable energy with conventional energy of European countries.

1. Name of the project:

Conceptual plan to integrate all renewable energy with conventional energy of all European countries.

2. Background:

Efficient, clean and green energy is the dream of world today. Of course, it is the same with European countries. Energy reliability and energy security is the vital amplitude of for the countries. The depletion of crude and coal which are the main conventional main source of the energy has worried the whole world. In 2019, the European Unions (EU-27) gross electricity production was nearly 2900 terawatt-hours. The biggest producer of energy was Germany, generating 607 terawatt-hours. The alternate source of energy is-

1. Solar thermal

2. Solar photovoltaic

3. Wind power

4. Hydro

5. Biomass

6. Geothermal

The above energy may be used as green energy with minimal carbon emission. The continuity of power will be more important for country member.

3. European Grid Centre (EGC):

European grid centre will be located at central place to coordinate among all countries. Expenditure not incurred by country member will be borne by EGC. Expenditure done in pool will be monitored in the ratio of MWH.

4. MIS:

EGC will generate MIS (monthly information sheet) for all country members to view and take corrective action accordingly time to time. Software will be developed to view the data by members sitting remotely.

5. Administration:

Bulk energy consumer may be head. From other members will be sub head and executive members.

6. Annual publication:

EGC will publish annual data/magazine in which data of all country members will be published like energy generated carbon saved per MWH, cost of energy ETC.

7. Annual Summit

Annual summit will be held every year. The country member will share their input like saved carbon emission, case study, failure and intuitive taken etc. A trophy will be provided to the country where carbon save is higher per MWH.

8. Centralized Energy Audit

Energy manager and auditor will be required for audit of individual country member. Auditor will fine the gap analysis and recommend for corrective action and country member will comply them. Motivation drive should be run for energy conservation in the industry, manufacturing unit and other commercial places.

9. Challenge:

There will be challenges in recycling after the useful life of equipments. we have to list out the sources of renewable energy , waste material component for recycle to make the environment clean and green.

a) Waste management: Normally two types of waste metal and e-waste will be generated where recycling will b required. A cell under EGC will remain functioning to overcome this problem.

b) E-waste: semi conductor wafer is the big challenge for the world. We have to research on it. LEAD produced is the major element that pollute water thereby danger produced for human and water animal.

10. Research:

Our strategy should be to establish research and lab to keep track in the world how to cultivate green and efficient eco-environment energy. In the research lab, candidate should be nominated from all country members and selection should by interview. it should be on deputation basis for 3-4 years.

11. Transmission methodology

A team under research will study the trend and latest development in the word. The team will formulate voltage profile, safe operation and maintenance. Topic should cover the distribution with low cost, high reliability and long life.

12. Tariff:

Tariff should be decided if it is more than generation of the country member. the metering system should be installed at EDC working as Centralized Data Centre.

13. Energy storage:

Energy storage should be also a part of research team. Energy storage methodology like aluminium air or lithium cell is some new development. We have to find more efficient and eco-environment green energy more durable with optimal cost.

14. International solar alliance (ISA)

EDC may be the member of such energy oriented organization to track and make changes as and when required.

15. Import/export of energy

Future requirement or surplus energy can be studied. ti-up can be explored to maintain power continuity.

16. Pollution control board:

EDC may provide its observation to individual country PCB and PCB will make regulation as it finds convenient.

Subscribe to:

Comments (Atom)

SOP for pest control or disinfestation in substation and switchgear rooms

1. OBJECTIVE a) To prevent the entry of lizards, rodents, and other pests inside electrical substations, MCC rooms, UPS rooms, battery rooms...

-

Winding and weight of induction and submersible motor – winding weight and motor weight Typical motor, 3 Ph, 40 H, 415v Sr. ...

-

Busbar Bus bar A bus bar (also spelled busbar, buss bar or busbar), is a str...

-

TRANSFORMER 11/0.415 KV Sr TR KVA Un tanking Mass (core+ winding), KG Oil Mass, KG Total mas...